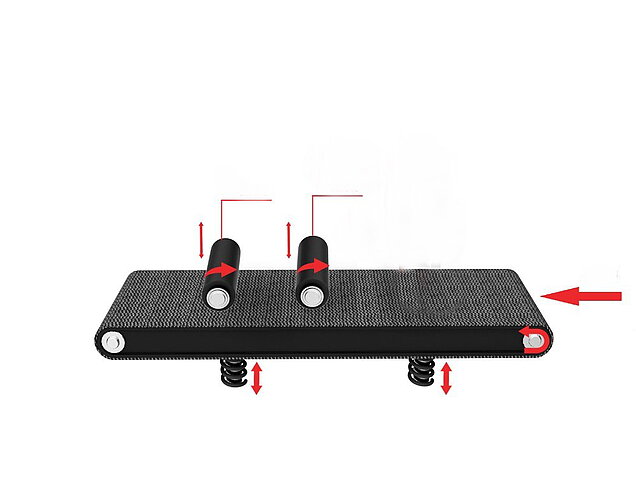

Brush roller

In comparison to sanding using a sanding belt the fleece rollers of the PSB B-unit create an even more consistent matt or matt-finished surface. They are available in different grains between very fine and very rough. The fine glazing marks add up to a decorative surface. The special orientation of the roller guarentees the longest possible useful life of the abrasive.

Fleece and Anderlon brush rollers can be optional dressed by means of an automatic dressing device inside the machine. This minimizes the maintenance effort for dressing the brush roller to an absolute minimum. This procedure can be repeated several times ensuring the creation of an even and reproducable surface for a long period of time.

In addition to fleece and Anderlon brush rollers, brush rollers out of stainless steel or other metal strands can be used.

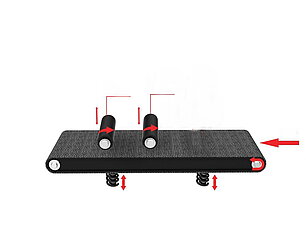

Brush head - Brush roller head

Brush head for deburring, punched parts, removing the secondary burr after pre-grinding with a coated abrasive belt or brushes on laser, plasma, flame or water yet cut parts. Also suitable for surface finishing of stainless steel, mild steel, aluminium, copper, jet, etc. using Scotch-Brite, slashed coated abrasive, mild steel wire, stainless steel wire or nylon impregnated wire. The choice of the material will determine the application.

A non-woven, synthetic fibre and an abrasive mineral are bonded together using a polymer adhesive to form a tough, chemically resistant, conformable and long-lasting abrasive material. Non-woven materials are also known under the trade name Scotch-Brite. In general, the non-woven material can be used in the manufacture of Flap Wheels, Discs, or as a wrapping around laminated paper tube. The different types and grit sizes will determine the end result and the life time of the brush.

Brushes with slashed coated abrasives are mainly used in deburring and edge radiussing.

The wire brushes with e.g stainless steel, mild steel and nylon impregnated wire are used for deburring and more specific in removing the secondary burr.

The slide system build in the machine, simplifies the change between different brushes.