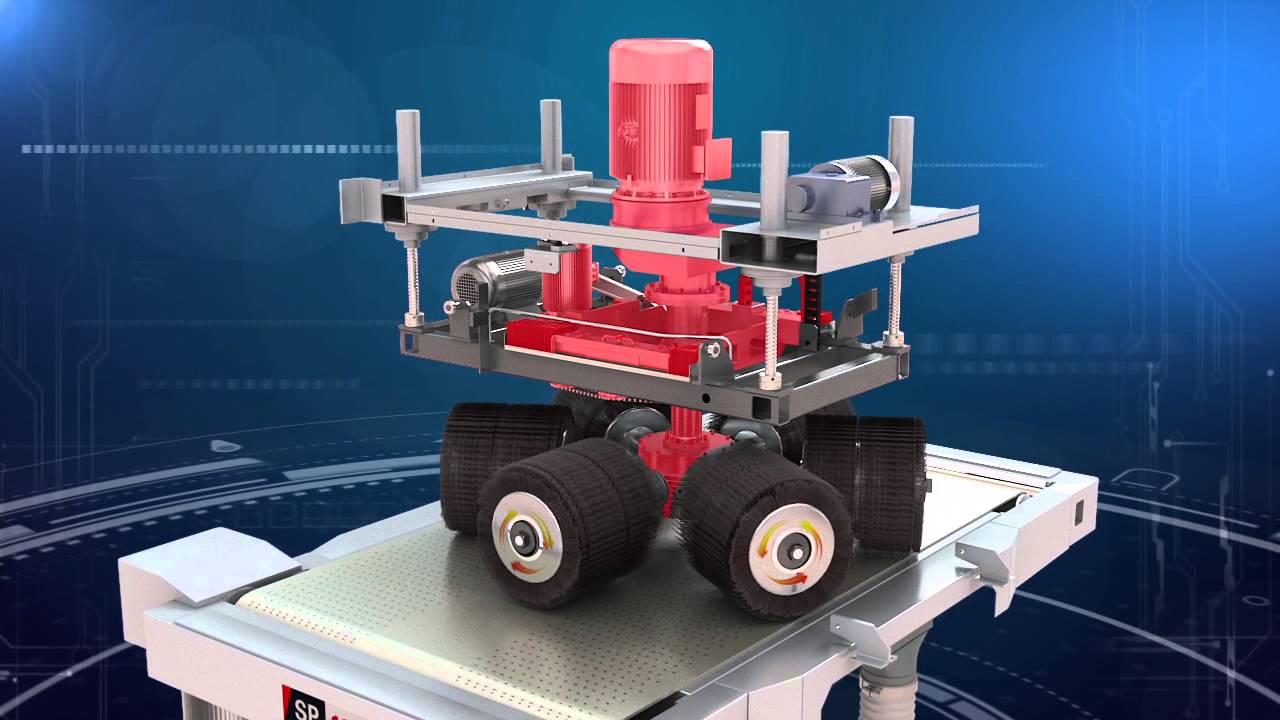

Deburring technology with gyroscopic Planetary rotating barrel brushes and contact roll with wide abbrasive belt

Optimal deslagging, deburring and corner rounding.

Metal deburring technology gradually evolved from the rather rough removal of unwanted machining remnants to a sophisticated technology for applying the finishing touch to precision parts from sheet metal. This evolution originated from the understanding of primary and secondary burr formation.

A so-called primary burr can be removed by making a grinding belt move in ‘with feed’ mode. The primary burr disappears, but a secondary burr occurs inside the hole due to plastic deformation of the primary burr [If the belt was moving in ‘against feed’ mode, a secondary burr would occur at the other side of the hole].

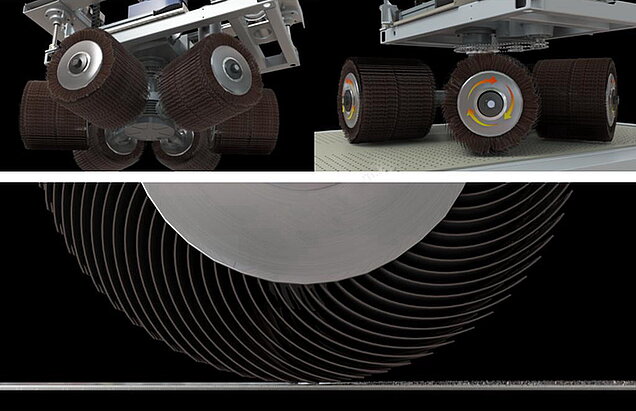

The solution to this problem: using a gyroscopic planetary rotating barrel brush!!!

This is a rotating brush with slabs of grinding cloth, which tend to protrude outwards thanks to centrifugal forces. Those slabs penetrate into holes from all differnt directions and attack angles and remove the secondary burrs. Depending on parameters such as rotational speed, slab stiffness, type of abrasive, product material, etc., the edge of the hole is rounded off with a radius between nearly 0 and about 2 mm.

How Your Shop Can Deburr MUCH more in Less Time with Gyroscopic Planetary Rotating Barrel Brushes from Profimach/Jonsen-Sander?

PRO Steel® PSG Versatile Series - PRO Steel® PSRG Versatile Plus Series

Deburring can be one of the most important, time consuming, and expensive operations – especially if your shop is still doing it manually. Automated deburring machines (like Profimach’s rotary brush barrel machines) eliminate the hassle and give you uncompromised speed, accuracy, and consistency to deliver better results.

What is a Gyroscopic Planetary Rotary Barrel Brush system?

A deburring machine is designed to eliminate burrs, sharp edges, and other imperfections from parts by applying motion or pressure to remove minute amounts of material. With rotary Barrel-brushes, workpieces get pushed against rotating, reciprocating, and/or oscillating brushes to clear away flaws and produce a perfectly finished piece. Rotary Barrel brushes can be safely used with a range of materials including stainless steel, aluminum, mild steel, and copper without harming coatings, plating, and ink-marked parts.

6 Benefits of Using a Rotary Brush Barrel

- Can Deburr Exotic Materials: This includes materials such as laser-guard and cladded aluminum.

- 360 Degree Attack: By attacking the burrs from 360 degrees it can easily deburr holes, edges leading and trailing, and shapes equally.

- Large Dwell Time: As the rotary brush-barrel rotates, the brushes are counter rotating and the entire carousel spins. This creates a large dwell time for the brushes to work on the material. The parts are attacked from the barrel brushes from each direction and each angle possible with result a much better deburring.

- Can Run Dry: There’s no need for coolant. Different materials can be run without changing the brush and parts stay dry, which eliminates the need for expensive drying processes.

- Comes with a Vacuum Conveyor Belt: That will allow for the running of small parts.

- Consumable Costs are Significantly Less than Belt Sanders: It’s easily 1/2 to 1/3 the cost.

PRO Steel® Versatile Series - Based on Planetary abrasive barrel brushes

Proven High efficiency and cost effective deburring, edge rounding

PRO Steel® Versatile PSG - Versatile Series

High efficiency and cost effective deburring, edge rounding

Focused on Light Deburring

Gyroscopic planetary abrasive brush Barrels

Width: 800 / 1000 / 1300 / 1600 mm

PRO Steel® Versatile PLUS PSRG - Versatile PLUS Series

High efficiency and cost effective deburring, edge rounding, and surface finishing machine

Focused on Deburring

Wide abrasive belt + planetary abrasive brush Barrels

Width: 800 / 1000 / 1300 / 1600 mm

BEST SELLER !!

Pro Steel® PSG Versatile Series

Focussed on automatic deburring, deflashing, corner rounding, oxide removal

| Pro Steel® Versatile Series | ||||||||

|---|---|---|---|---|---|---|---|---|

| PRO Steel® Series | Small Bur removal | Bur removal | Slag removal | Edge Rounding | Laser Oxide removal | Rust Removal | Surface finish | Calibrating |

| PSG - Versatile Series | ++++ | +++ | + | +++ | +++(opt) | ++++(opt) | + | - |

| PSRG-Versatile PLUS Series | ++++ | ++++ | +++ | +++ | ++++(opt) | ++(opt) | ++ | - |

PRO Steel Series : Code key = P-x-S-y-z-000-w

How to read the machine types?

| Code | P-x-S-y-z-000-w | component unit |

|---|---|---|

| x | Digit between P-S | |

| 2 | Two sides simultaneously up and down deburring | |

| y | First digit after PS (Profimach Sander) | |

| - | Automatic operation | |

| M | Manual operation | |

| z | codes placed in sequence of machining | |

| 2-3-4-5-6 | Number BEFORE letter is the quantity of the letter following | |

| B | Brush full width | |

| C | Chain Belt transversal | |

| D | Disk brush vertical | |

| H | Disk Brush vertical with hammer function | |

| G | Gyro or planetary barrel brush or fladder type | |

| R | Roller- Contact roller with full width abrasive belt | |

| T | Transversal Small Belt | |

| OOO | Width of working surface in mm | |

| w | at the end after width value | |

| W | Wet working | |

| II | Second Generation | |

| III | Third Generation | |

| - | Dry working |

Profimach is renowned for offering the world’s broadest and most affordable line of industrial metal finishing machines.

Its rotary brush-barrels are built to deliver everything your shop needs: perfect edge rounding, low tooling costs, and variable handling for materials of different types, thicknesses, and sizes.

Profimach’s two most popular models based on gyroscopic planetary rotary barrel brushes are:

-

The PRO Steel® PSG Versatile Series is offered in 800 mm, 1000 mm, 1300 mm and soon in 1600 mm wide models.

-

The PRO Steel® PSRG Versatile PLUS Series is offered in 800mm, 1000mm and 1300 mm wide models equipped with an extra full width abrasive belt Roller for eliminating all big burrs and slag before the Gyroscopic barrel brushes take over.

Profimach’s rotary brush-barrels are engineered to fully and uniformly deburr your part’s rough edges. They can be safely used with flat, shaped, and 3D workpieces and won’t harm coatings like laser film, cladding, or zinc.

Whether your shop uses a laser cutter, a punching machine or plasma cutter, Profimach’s rotary brush-barrels help you produce flawless products and unparalleled results every time.

Deburring of 3D parts on PSG-Series

Optimal deburring of light 3D formed parts or parts with protrusions and surface forms on the top and/or bottom faces of the part.

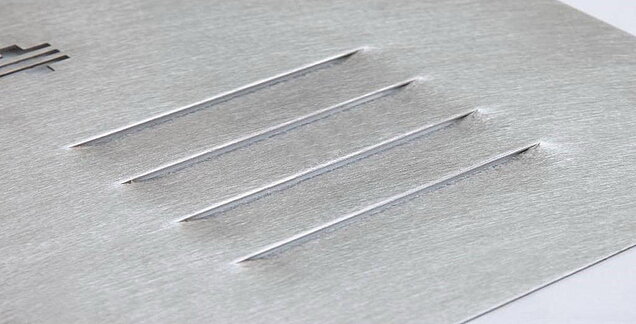

Sample of deburring parts with protection folie

DEBURRING, EDGE ROUNDING, FINISHING AND OXIDE REMOVAL

The Deburring, Edge Rounding, Finishing and Oxide Removal Machine PSG-Versatile Series is a metal deburring machine for sheet metal and parts cut by punching, shearing, laser or plasma.

The PSG-Versatile Series features an integrated vacuum table and a 3 movement system of the brushing head, assuring high consistency. It is possible to work metal sheets and metal parts up to 1600 mm width and some as small as 50x50mm.

This machine can perform rounding on small holes, bended plates and create big radius up to 2mm.

By blocking the rotation head this machine can be used for metal surface finishing in a configuration of wide belt and double parallel brush.

On this machine it is easy to interchange brushes, so it is possible to achieve rounded edges free of burrs or sharp corners but also cleans the oxide layer of the sides.

When operating with steel planetary brushes, this Deburring, Edge Rounding, Finishing and Oxide Removal Machine removes efficiently the oxide layer on interior and exterior contours of laser-cut steel sheets.

Profimach deburring machines, Jonsen Sander deburring machines, Jonsen sander, deburr and edge round punched/stamped and laser-cut parts, double-sided deburring, single side deburring, Oxide removal and surface finishing, deburring, deburring machine, deburring Machines, FLAT DEBURRING MACHINE, plate deburring machine, sheet deburring machine, deburring solution, automated deburring, edge rounding, edge processing, rounding, deburr and edge round, clean edge, oxide removal, surface finish, grinding, hand grinding, double-sided, single-sided, single pass, punched, laser, laser beads, cut, thin sheet metal, parts, burrs, splatters, light burrs, laser deburring, high quality results, small parts, brushes, quick change, three dimensional, industrial sheet metal processing, economical deburring, Metal Polishing Machines, deburring brush, metal parts with burrs, sheet metal with burrs, metal parts with burrs, punched parts with burrs, laser parts with burrs, plasma parts with burrs, flamecut parts with burrs, heavy burrs, light burrs,