Gyro barrel brushes

Gyro - Planetary barrel brushes - Fladder type brushes

With this G-unit unit Profimach PSG Type can remove even very rough slag and oxides without any difficulty. In addition the typical Gyro surface can be created.

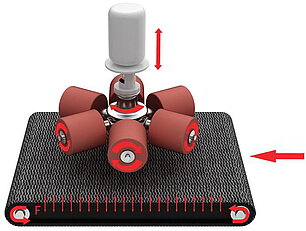

The four/six spindles of the sanding head of the Gyro unit rotate pairwise in opposite directions (clockwise / counterclockwise) to realize a homogeneous sanding of the work pieces as well as an even wear of the abrasives. The sanding head rotates with the four/six spindles on its own axis and oscillates over the width of the conveyor belt.

The Gyro unit can be equipped with abrasive cylinders, deslagging or oxide removing tools in different diameters and lengths.

Technology

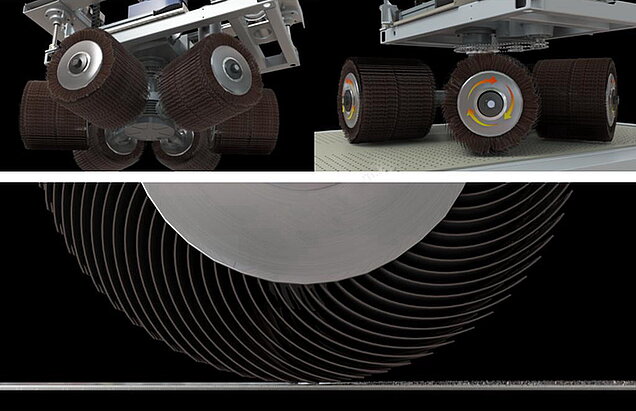

PRO Steel® Fllexy Series

The planetary gear head: unique technology

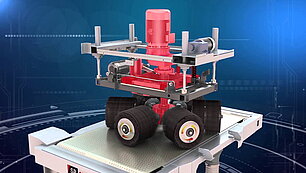

The gear head is a very solid construction. The housing of aluminium has outside cooling ribs and inside room for the toothed wheels in chrome vanadium steel. The force from the main motor is transferred directly to the 4/6 spindles.

Efficient processing of the workpieces.

The gear head with the main motor and rotatin motor is mounted on a scissor suspension frame. The scissor is equipped with special hardened, grinded wheels. It makes it possible to create the linear, oscillating movement across the conveyor belt. This - combined with the in pair counter rotating spindles - results in uniform workpieces and uniform wear of the tools.

Technology based on the centrifugal force

The pressure towards the workpieces are created by means of the centrifugal force, specifically through regulation of the rpm. The Planetary technology is a non-aggressive system and the abrasive Barrel brushes/cylinders brushes are flexible tools. It means that besides flat workpieces also bended, shaped and 3 dimensional workpieces can be processed.

PSG-Series

Gyroscopic Planetary Rotary Barrel Brushes

Rotating planetary brush

Rotating carousel with 2/4/6/8 abrasive flap brushes; 1/2/3/4 rotating clockwise and 1/2/3/4 rotating counter-clockwise for uniformly deburring and rounding edges of laser plasma cut, punched and machined parts in all directions. Processing different work piece thicknesses simultaneously (up to 5 mm difference) in one single, simple set-up. Flat parts, but also parts with protrusions and surface forms on the top and/or bottom faces of the part. Small parts held by the standard vacuum table.

G-unit: Gyro Type - Planetary barrel brush type

PSG: Planetary rotating Gear head mounted with multiple rotating barrel type brushes

A Gyro (fladder type) type unit is equipped with a powerful gear head mounted with 2/4/6 cone spindles on which different kind of barrel brushes can be used.

The spindles are in pairs counter rotating while the complete gearhead is performing an oscillating and rotating movement over the surface of the work piece.

G- Unit : Gyroscopic Planetary rotating horizontal Barrel Brushes

STANDARD FEATURES

The G-unit is a flexiable deburring Unit which is mainly for flat plate and milling parts. This unit is equipped with abrasive barrels on the head, each one spins while the whole head rotates.

It can deburr on all edges and gets deep into holes while grinding, scraping, cutting and filing. .

- Dry operation

- Max. working width: 800/1000/1300 mm

- Machine opening: 120mm

- Metal presicion deburring and edge rounding

- Capable of processing minor profiled (3D) parts

- Equipped with planetary abrasive barrel station

- Equipped with vacuum conveyor bed to hold down small part

- Respect folie cover

- Perfect deburring and edge rounding

- Very effective in de-oxiding by special steel brushes