PSRD-Series

Flexible and efficient deburring, edge rounding, and finishing machine

Deburring, edge rounding, and flash removal for punching, shearing, laser cutting parts. It keeps parts original thickness, deburring and rounding the edges and holes on the parts.

PSRD-Series

Flexible and efficient deburring, edge rounding, and finishing machine

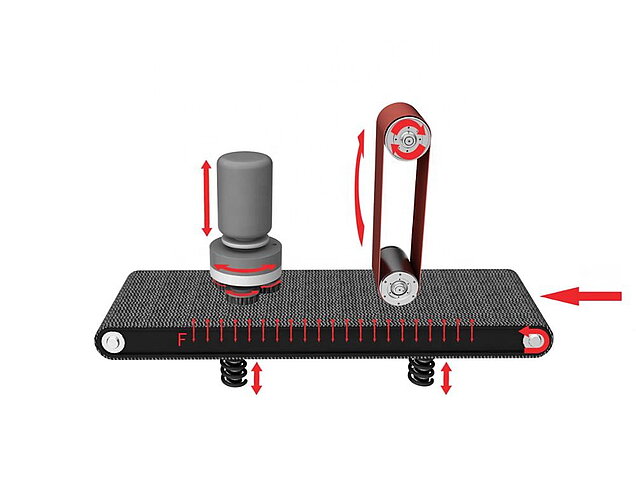

PSRD-Series would be best suitable for deburring, edge rounding, as well as surface sanding and finishing of punching, shearing, laser cutting parts. It is equipped with 2 work stations: a wide abrasive belt head and a zig-zag disk brush station.

Machine characteristic overview:

-

Dry operation, therefore low production and maintenance cost. The machine usually has a long life which means the return on investment is high

-

Conveyor feed through type, high efficiency

-

First wide abrasive belt head for initial sanding, and zig-zag disk brush station for deburring and edge rounding. Each station can work individually or together

-

Other combinations of work stations are also available

-

Optional magnetic or vacuum conveyor bed to accommodate and process small parts

-

Straight forward and user-friendly operation

-

Auxiliary LED lighting inside machine

-

Dust collection hood is installed inside the machine

| PSRD-Series | magnetic table | width belt | Belt speed | min length | min dimension part(magnetic) | Max width parts | Thickness | Zigzag Top brush | Top brush speed | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PSRD-300 | yes | 300x1900 | 0,5-5m/min | 300 mm | 30x30 | 300 mm | 1-80mm | 3 x 165 mm | 1-60 r/min | ||||

| PSRD-630 | yes | 630x1900 | 2-11 m/min | 270 mm | 50x50 | 600 mm | 1-80mm | 5 x 165 mm | |||||

| PSRD-1030 | opt | 1030x1900 | 2-11 m/min | 250 mm | opt | 1000 mm | 1-80mm | 7 x 165mm | |||||

| PSRD-1030 | opt | 1300x1900 | 2-11 m/min | 250 mm | opt | 1280 mm | 1-80mm | 7 x 165mm | |||||