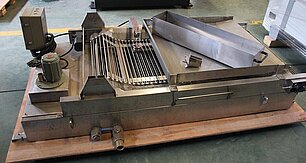

Machine based on our proven Contact roller unit

R-unit with abbrasive wide belt

The R-Type contact roller unit reliably removes any burr and generates a uniform structure on the surface of the work pieces. The edges can be rounded in this process, too. The contact roller units work with a rubber-coated steel roller (standard hardness 60° Shore) with a big diameter mm and can be equipped with frequency controlled drive motors with up to 32 kW . Sanding belt speeds between 1.2 m/s and 32 m/s are possible. The surface of the roller is grooved in a spiral shape. This allows a better cooling of the roller and makes it easier to extract the generated abrasive dust. Premature grain break-outs are minimized due to the special orientation of the contact roller units on the machinery base. There are nearly no oscillation marks visible and the useful time of the sanding belts is increased to a multiple. The sanding result remains consistent for a longer time.

Belt head or Roller head with wide abrasive belt

The choice of the abrasive belt will be determined by the application: deburring or finishing.

Wide abrasive belt for pre grinding heavy burrs from laser, punched and water jet cut parts. Also suitable for surface finishing of stainless steel, mild steel, copper, aluminum etc. using coated abrasives or Scotch-Brite belts.

Using a variety of endless coated abrasive belts and a differing shore hardnesses of the contact roller will result in various solutions for numerous applications. A soft roller will provide a bigger edge rounding and less surface damage; a hard contact roller will remove more material on the surface and less rounding of the edge.

With the standard pneumatic rise & fall movement the head can be quickly put in down position when used or put in neutral position when not used. The locking system for an easy and quick belt change provides you with the flexibility to choose between deburring and finishing within minutes.