PSR-Series

Our most popular, most budget friendly and must sold universal deburring - grinding machine

PSR-350/630/1030/1300 Series

Our very popular and good sold universal budget friendly Dry deburring machine

PSR-350/630/1030/1300 is a budget friendly very versatile machine model. The wide abrasive belt head is capable of sanding down and removing the bigger burrs on the parts, or using it for whole surface finishing purpose such as No.4 finishing.

The planetary abrasive barrel station that consists of 4 abrasive barrels (2 in clockwise rotation, and 2 in counter-clockwise rotation) will further rounds the edges and the contours. It is suitable for parts from laser cutting, punching, shearing, and etc, generally with small/medium burrs and sharp edges. It produces much more consistent result of deburring and edge rounding in significantly higher efficiency than using manual tools.

There will be no more metal dust just dispersing into the air with the optional wet dust collecting device, which will be efficiently extracted from the machine.

Basic Machine characteristic overview:

- Dry operation

- Wide abrasive belt head for sanding out the burrs or surface finishing

- Conveyor table

- Long life span of consumables

- Straight forward and user-friendly operation

- Auxiliary LED lighting inside machine

- Dust collection hood is installed inside the machine.

PSRD-Series

Our very popular universal deburring, finishing and edge rounding machine

PSRD-300/630/1030/1300 Series

Our very popular universal deburring, finishing and edge rounding machine

PSRD-300/630/1030/1300 is a budget friendly very versatile machine model. The wide abrasive belt head is capable of sanding down and removing the bigger burrs on the parts, or using it for whole surface finishing purpose such as No.4 finishing.

The vertical oscilating vertical brushes will further rounds the edges and the contours. It is suitable for parts from laser cutting, punching, shearing, and etc, generally with small/medium burrs and sharp edges. It produces much more consistent result of deburring and edge rounding in significantly higher efficiency than using manual tools.

There will be no more metal dust just dispersing into the air with the optional wet dust collecting device, which will be efficiently extracted from the machine.

Basic Machine characteristic overview:

- Dry operation

- Wide abrasive belt head for sanding out the burrs or surface finishing

- Oscilationg vertical brushes

- Conveyor table

- Long life span of consumables

- Straight forward and user-friendly operation

- Auxiliary LED lighting inside machine

- Dust collection hood is installed inside the machine.

PSRG-Series

Our most popular and must sold universal and very versatile deburring machine

PSRG-800/1000 Series

Our most popular and must sold universal and very versatile deburring and edge rounding machine

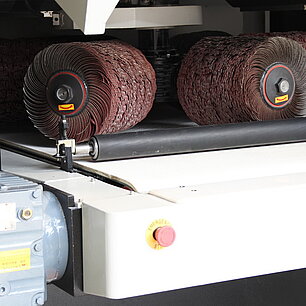

PSRG-800/1000/1300/1600 is a very versatile machine model. The wide abrasive belt head is capable of sanding down and removing the bigger burrs on the parts, or using it for whole surface finishing purpose such as No.4 finishing. The planetary abrasive barrel station that consists of 4 abrasive barrels (2 in clockwise rotation, and 2 in counter-clockwise rotation) will further rounds the edges and the contours. It is suitable for parts from laser cutting, punching, shearing, and etc, generally with small/medium burrs and sharp edges. It produces much more consistent result of deburring and edge rounding in significantly higher efficiency than using manual tools. There will be no more metal dust just dispersing into the air, which will be efficiently extracted from the machine.

Machine characteristic overview:

- Dry operation

- Wide abrasive belt head for sanding out the burrs or surface finishing

- Planetary type abrasive barrel station for further edge rounding, 4 abrasive barrels, and planetary rotation possible to replace for oxide removable brushes

- Vacuum conveyor table to accommodate small parts, smallest parts available 50x50mm

- Planetary abrasive barrel station will only focus on the edges and contours of the parts, minimum effect on the whole surface

- Capable of processing minor formed/profiled parts

- Long life span of consumables

- Straight forward and user-friendly operation

- Auxiliary LED lighting inside machine

- Dust collection hood is installed inside the machine.

PSHTC/PSDTC-Serie

Deslagging, deburring and edge rounding machine with the latest high tech inside

PSHTC/PSDTC-Serie - PRO Steel Wipe Series

Medium-thick metal parts de-slagging and edge rounding machine

The machine is capable of efficient de-slagging and edge rounding of medium-thick metal parts after oxy-fuel, plasma, or high power laser cutting processes.

1st work station is equipped with zig-zag patterned hammer type de-slagging disk station (H) for knocking out the heavy slags. 2nd work station can configure either one more hammer/brush type de-slagging/Deburring disk station (H/D) for further de-slagging (usually for parts with a good amount of slags) or one more narrow Transversal abrasive belt head (T) for sanding on leftover molten slags (usually there are molten slags at piercing point, it has to be sanded down by abrasive belt head). 3rd work station is equipped with horizontally arranged wiping chain crossbelt station (C) for final edge rounding and surface smoothening.

The advantages are significant that the machine has low cost on consumables, creates minimum noise and metal dust during the production. The operation is very straightforward and user friendly. With such 3 work station configuration, the machine can achieve the optimal performance on de-slagging. It is a perfect solution to release manual labor from tedious de-slagging work!