Profimach® PRO Steel® Line offers quality machines for

the deburring, edge rounding, de-slagging, surface finishing, calibrating, oxide removal and rust removal

of thin and medium-thick sheet- and plate metal parts

after laser cutting, punching, shearing, blanking, plasma cutting or oxy cutting.

PRO Steel® Line : Built for Europe by Jonsen Sander

PRO Steel® Series: 6 lines of Machines

Manual-Series - Versatile-Series - Flexy-Series - Wipe-Series - Surface Finish-Series - Dual side-Series

PRO Steel® M Series - Based on Manual operation

Manual flexibility and precision

PSDM-Manual

Swing arm deburring and grinding genius

PSDM-Manual

PRO Steel® M-Series:

Manual Deburring + Grinding machine

PSTM-II Manual

Foir this BIGGER precision surface finishing jobs

PSGM-II Manual

Pro Steel® M-II Series

Double abrasive belt stroke sander

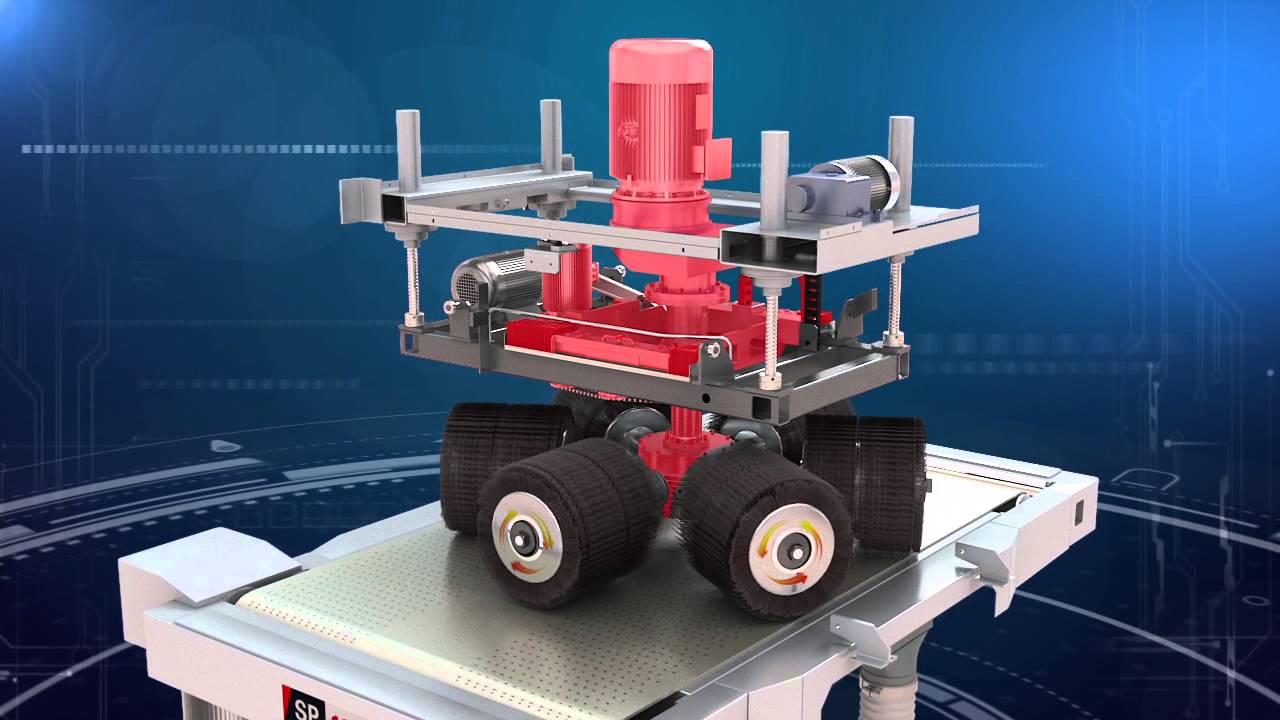

PRO Steel® Versatile Series - Based on Planetary abrasive barrel brushes

PSG- Series: Proven High efficiency and cost effective deburring, edge rounding

PSG-Versatile Series

PSG-Series: Based on Gyroscopic Planetary abrasive barrel brushes

The Planetary technology is a non-aggressive system and the abrasive Barrel brushes/cylinders brushes are flexible tools. It means that besides flat workpieces also bended, shaped and 3 dimensional workpieces can be processed. Also coatings and folies are respected and not damaged

PRO Steel® Versatile Series - PSG-Series

High efficiency and cost effective deburring, edge rounding

Focused on Deburring

Gyroscopic Planetary abrasive Barrel Brushes

Width: 800 / 1000 / 1300/ 1600 mm

PRO Steel® Versatile PLUS PSGP - Versatile PLUS Series

High efficiency and cost effective deburring, edge rounding, and surface finishing machine

Focused on Deburring and very heavy deburring

Wide abrasive belt + planetary abrasive brush Barrels

Width: 800 / 1000 / 1300 / 1600 mm

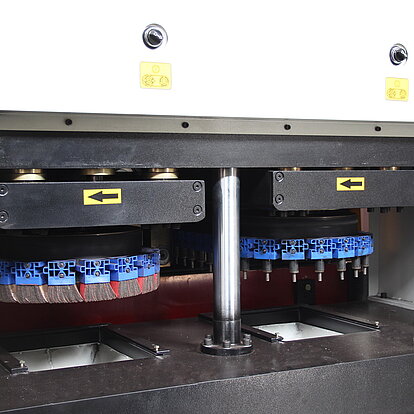

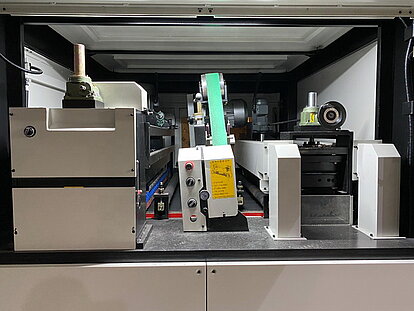

PRO Steel® Flexy Series - Based on vertical brushes

PSD-Series: Proven High efficiency and cost effective deburring, edge rounding

PSD Flexy Series

PSD-Sereis Based on vertical brushes

Flexible and efficient deburring, edge rounding, flash removal and finishing machine. It keeps parts original thickness, deburrs and rounds the edges and holes on the parts smoothly.

PRO Steel® Flexy PLUS Series - PSRD-Series

High efficiency and cost effective deburring, edge rounding, and surface finishing machine

Focused on Deburring

Wide abrasive belt + planetary abrasive brush Barrels

Width: 800 / 1000 / 1300 mm

PSR3D Serie: PRO Steel deburring series

High efficiency and cost effective deburring, edge rounding

High profile parts deburring like gears, flanges, cams, etc

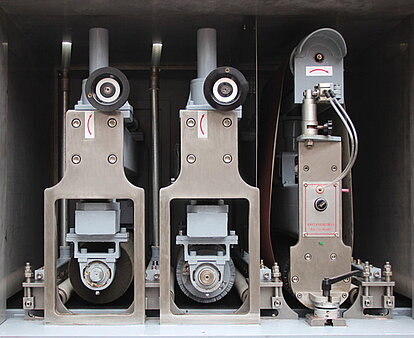

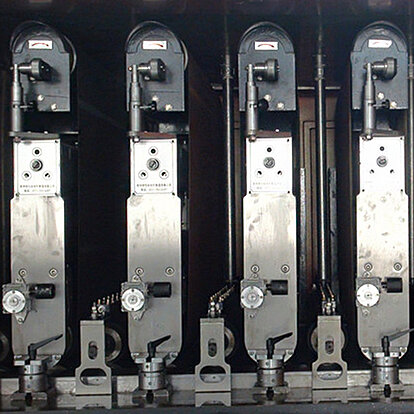

PRO Steel® Wipe Series - Based on Abrasive belt chain.

PSC-Series: Based on Abrasive belt chain. Proven High efficiency and cost effective deburring, edge rounding

PRO Steel® Wipe Series

PSC-Series : Based on Abrasive belt chain.

Parts deburring and edge rounding machine focused on contours and edges ONLY.

Modular system, combination of differnt technologies possible in one chain.

PSRC-Series Wipe

Deburring and finishing machine based on modular Chain belt

PRO Steel® Wipe Plus Series - PSCC-Series

Based on two abrasive Modular chain belts

PSTC-Series: PRO Steel Wipe Plus Series

Based on Transversal Chain belt brushes

PSHTC- Wipe plus Series

Hammer unit to deslag - TRansversal belt to debur and deslag rest of slag - Chain belt to deburr and finish final surface

Latest deslagging -beburring- finishing devellopement in the market!

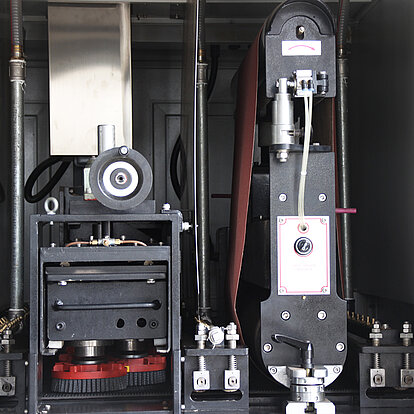

PRO Steel® Surface Series - Based on contact roller with wide Abrasive belt.

PSR-Series: Focus on automatic Finishing, calibration and surface quality

PRO Steel® Surface Finish Series

Based on abrasive horizontal wide belts and full width brushes, Focus on surface finish

PRO Steel® PS2R

Automatic DRY surface Finishing machine

PRO Steel® PS2R- Series

Single Side - DRY

2 wide belt station

PRO Steel® PS3R Series

PRO Steel® PS4R

Automatic DRY surface Finishing machine

PRO Steel® PS4R- Series

Single Side - DRY

4 wide belt station

PRO Steel® PSRB-W Plus Surface series

Automatic WET surface Finishing machine

PRO Steel® PSR-W Series

Single Side - WET

PRO Steel® PSRBBW-PLUS Surface series

Automatic WET surface super Finishing machine

PRO Steel® PSR-W Series

Single Side - WET

Brilliant Finish result

PSRB-W - Series

Full sheet surface sanding, grinding and finishing machine

Automatic WET surface Finishing machine

Single Side - WET

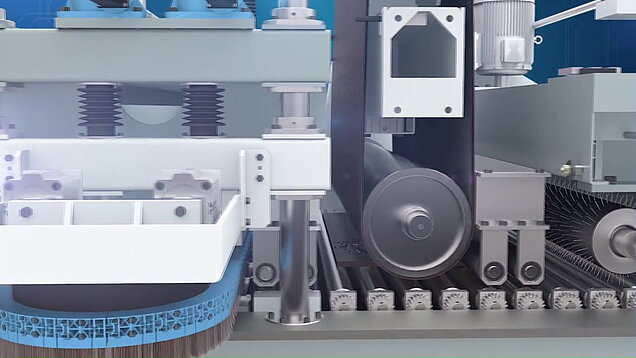

PRO Steel® Auto Dual Side Series - Base on two sides simultaneously deburring

PS2-Series: Automatic deburring and grinding of both sides

PS2 - Series

Dual side deburring

PRO Steel® Dual: P2S-Series

Specific Machining Application

P2SDTC-Series:

High power laser cut parts, heavy slag removal, deburring machine and edge rounding

Two sides finished in one passing

PRO-Steel is also tailor-made deburring machines for enhanced quality in sheet metal.

Whether thick or thin parts, heavy or light burrs, oxidised or rusty surfaces: We offer a suitable deburring and finishing machine for punched, laser or plasma, flame-cut parts.

In order to offer you the optimal machine solution, we specifically focus on your parts and your edge processing requirements.

Ultimately, we strive to provide you with the best and most consistent parts quality, keep your investment affordable while achieving lowest costs per part.

Profimach deburring machines, Jonsen Sander deburring machines, Jonsen sander, deburr and edge round punched/stamped and laser-cut parts, double-sided deburring, single side deburring, Oxide removal and surface finishing, deburring, deburring machine, deburring Machines, FLAT DEBURRING MACHINE, plate deburring machine, sheet deburring machine, deburring solution, automated deburring, edge rounding, edge processing, rounding, deburr and edge round, clean edge, oxide removal, surface finish, grinding, hand grinding, double-sided, single-sided, single pass, punched, laser, laser beads, cut, thin sheet metal, parts, burrs, splatters, light burrs, laser deburring, high quality results, small parts, brushes, quick change, three dimensional, industrial sheet metal processing, economical deburring, Metal Polishing Machines, deburring brush, metal parts with burrs, sheet metal with burrs, metal parts with burrs, punched parts with burrs, laser parts with burrs, plasma parts with burrs, flamecut parts with burrs, heavy burrs, light burrs,