Pro Steel® Series

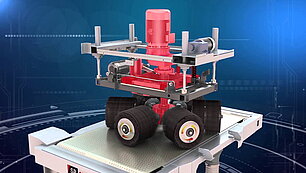

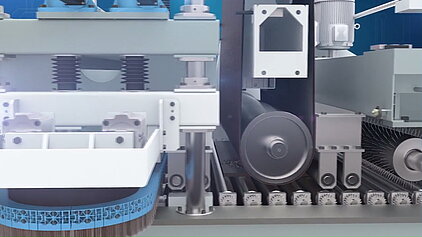

Building components

Pro Steel® Series features 6 different units: contact rollers or wide belt sanding/grinding units (R), Vertical single, multi or multi planetary disk brush (D) or Hammer units (H), Gyro / Fladder type units based on Planetary abrasive brush Barrels (G), full width brush roller units (B), small Transversal belt units (T) and recently developped chain belt brush units (C)

All units can be mounted on the base machine as well as on the extension modules without any constraints. Free spaces can be provided in the modules for upgrading at a later date.

Machine combination samples

We master ALL latest technologies in our field

Our different modular units available sorted alphabetical.

Search and combine to create the best solution for your applications or ask our specialist!

B-unit: Brush Roller Unit

PSB: Full Width Brush unit

C-unit: Transversal CHAIN belt unit

PSC: Full Width abrasive CHAIN Belt with exchangeable links build as brush, abrasive, polish units

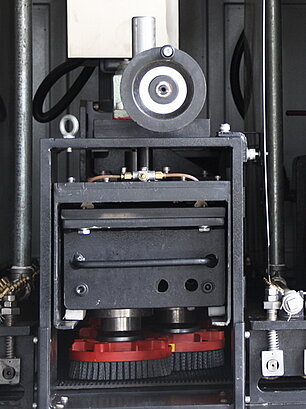

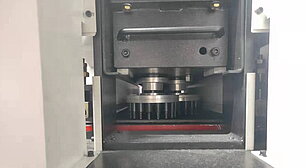

D-unit: Vertical Disk unit with brush function

PSD: Single Disk brush or multiple disk Brush or Planetary Disk brushes

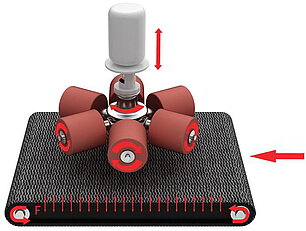

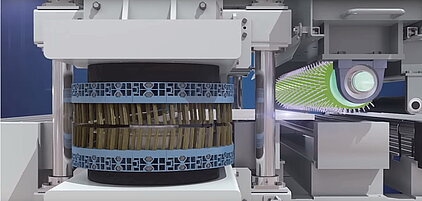

G-unit: Gyro Type - Planetary barrel brush type

PSG: Planetary rotating Gear head mounted with multiple rotating barrel type brushes

A Gyro (fladder type) type unit is equipped with a powerful gear head mounted with 2/4/6 cone spindles on which different kind of barrel brushes can be used.

The spindles are in pairs counter rotating while the complete gearhead is performing an oscillating and rotating movement over the surface of the work piece.

H-Unit: D-unit equipped with hammers for deslagging big burrs and slag

PSH : Single Disk hammer or multiple disk hammer to remove big burrs and big slag

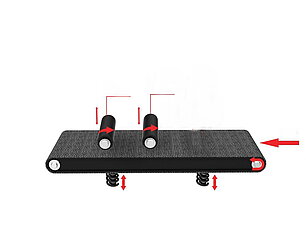

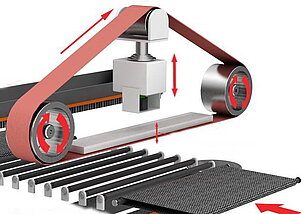

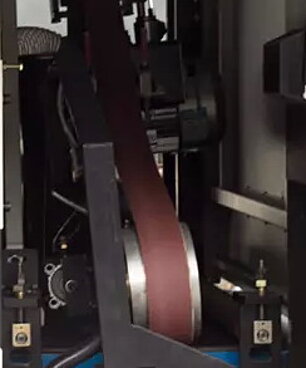

R-unit: Contact Roller with Full Width abrasive belt

PSR: Full Width abrasive Belt

T-unit: Transversal belt unit

PST: Small Belt transversal working over full width

PRO Steel Series : Code key = P-x-S-y-z-000-w

How to read the machine types?

| Code | P-x-S-y-z-000-w | component unit |

|---|---|---|

| x | Digit between P-S | |

| 2 | Two sides simultaneously up and down deburring | |

| y | First digit after PS (Profimach Sander) | |

| - | Automatic operation | |

| M | Manual operation | |

| z | codes placed in sequence of machining | |

| 2-3-4-5-6 | Number BEFORE letter is the quantity of the letter following | |

| B | Brush full width | |

| C | Chain Belt transversal | |

| D | Disk brush vertical | |

| H | Disk Brush vertical with hammer function | |

| G | Gyro or planetary barrel brush or fladder type | |

| R | Roller- Contact roller with full width abrasive belt | |

| T | Transversal Small Belt | |

| OOO | Width of working surface in mm | |

| w | at the end after width value | |

| W | Wet working | |

| II | Second Generation | |

| III | Third Generation | |

| - | Dry working |