Pro Steel® PSTM-II Manual

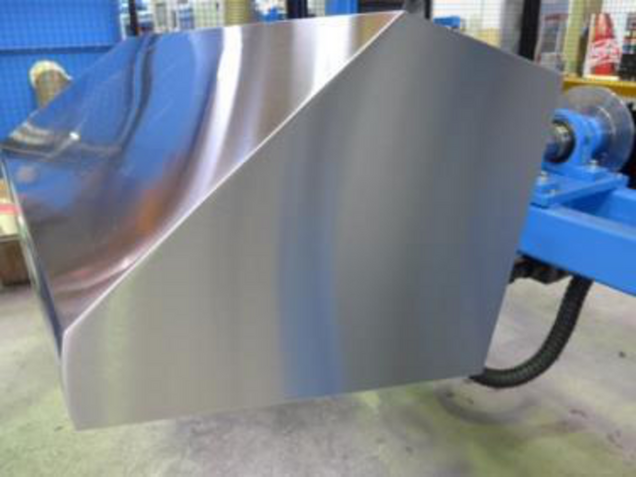

Double abrasive belt stroke sander

Surface grinding: Twin-Belt Grinding Machine

Our Pro Steel® PSTM-II Manual Twin Belt Grinding Machine is built for the roughing and finishing on welded edges, corners and surfaces on flat and mid-size workpieces out of steel, stainless steel, and aluminum, i.e. doors, frames, cabinets, housings, hoods, furniture parts, frame parts in automotive and aircraft - manufacturing, round bins, cylinders, heaters etc. It is the perfect machine to replace manual sanding and who can handle big and complex parts.

Our Pro Steel®PSTM-II Manual is widely used for surface finishing, polishing, and weld bead sanding of formed parts such as boxes, cabinets, doors, furniture, cabins, and etc. . The machine has two abrasive belt heads parallel to each other. Various type and grit of abrasive belt can be installed for specific applications. It is equipped with double working tables: patented vacuum holder for holding and affixing small enclosures, and the standard working bench for placing large enclosures and cabinets. It is ideal in processing electrical cabinets and enclosures.

Standard working width is 2500 mm, but optional you can get 3500 mm, 4500 mm and 6000mm

PSTM-II Manual Series

Twin long belt machine for metal sheets or welded structures weld grinding and finishing.

This machine is ideal for irregular shapes polishing as well as for weld removing. The flexible and adjustable table is useful when, because of the big dimension of the materials to be worked, you cannot move the piece.

PSTM-II Manual is a double belt finishing machine with flexible abrasive which enables the work of flat surfaces as well as corners or edges of materials.

WORKING TABLE

Table 2500mm (optional 3500-4500-6000) - 2 grinding stations

PSTM-II Manual has a working table of 2500x1500mm with a lift of 600mm which makes the finishing of large structures easy . By having 2 parallel abrasive belts ( 9000 x 100mm) with grinding belt speed of v = 2.5 - 14 m/s, the finishing of grinding and polishing can be done faster, by simply selecting the abrasive belt to work with. One belt is for grinding, the other for polishing.

With PSTM-II Manual you move the table by motor and use the adaptability of the long belt together with several grinding tools in order to work the areas you need.

INFINITELY POSITIONABLE WORKPIECE HANDLING DEVICE

For part sizes: minimum of 300 x 350mm, maximum 35KGS.

Easy unit movement by u-shaped table frame on 4 prism rollers

Bearing mounted at the table frame for arrangement of a turn mandrel of an aluminum pipe

Secure stop by a disc brake, brake torque 30 daNm by spring power

Repositioning of the brake pneumatically by a foot switch

Turn mandrel with integrated work piece swivel device with secure 0°, 45° and 90° position by a pneumatic activated blocking bolt

Additional ball head unit to reach every angle till 45°

Control by a foot pedal activated valves

Secure workpiece clamping by 4 adjustable vacuum valves located at the swivel device

Suction valves controlled by foot switch pedal

Vacuum clamping

STORAGE RACK TO CARRY SLIDING TABLES

Storage rack, positioned behind the machine, to store the two sliding tables (infinitely positionable Vacuum workpiece handling device table & Standard wooden flat table)

Advantages of the Twin-Belt Grinding Machine Pro Steel® PSTM-II Manual

- Savings of approx. 50% on working time by use of the 2 separate grinding belts for roughing and finishing: Only one handling and setup of the workpiece

- Further savings of approx. 25% by use of the handling device: The workpiece can be orientated on 5 axes and can be prepared on all sides in one operation

- Manually preparation and pre-grinding on welded seam can be avoided, because the grinding belts can be tensed very smooth and then rotated by 90°. The operator can reach almost all edges and corners of the workpiece and polish the surface

- High ergonomics by free access and view onto the workpiece

- Flexible with the table height adjustment

- Simple adjustment of grinding belt speed and pressure for belt tensioning

- Automated reduce of grinding belt speed by pushing the grinding belt cover, no further manual setup required

- Simple control of handling functionality by foot operation panel

- Fast and simple grinding belt changing by self-centering belt run