How Your Shop Can Deburr in Less Time with Gyroscopic Planetary Rotating Barrel Brushes from Profimach/Jonsen-Sander?

PRO Steel® PSG Versatile Series - PRO Steel® PSRG Versatile Plus Series

Deburring can be one of the most important, time consuming, and expensive operations – especially if your shop is still doing it manually. Automated deburring machines (like Profimach’s rotary brush barrel machines) eliminate the hassle and give you uncompromised speed, accuracy, and consistency to deliver better results.

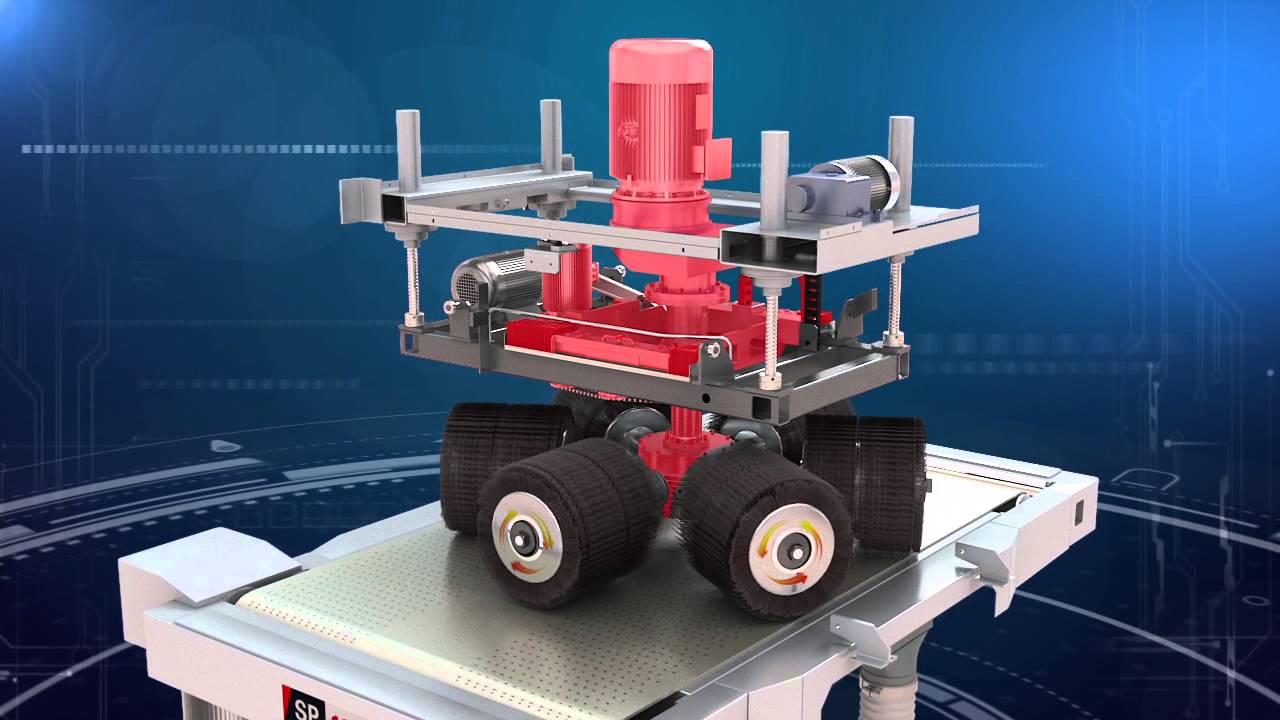

What is a Rotary Brush Barrel?

A deburring machine is designed to eliminate burrs, sharp edges, and other imperfections from parts by applying motion or pressure to remove minute amounts of material. With rotary brush-Barrels, workpieces get pushed against rotating, reciprocating, and/or oscillating brushes to clear away flaws and produce a perfectly finished piece. Rotary brushes can be safely used with a range of materials including stainless steel, aluminum, mild steel, and copper without harming coatings, plating, and ink-marked parts.

6 Benefits of Using a Rotary Brush Barrel

- Can Deburr Exotic Materials: This includes materials such as laser-guard and cladded aluminum.

- 360 Degree Attack: By attacking the burrs from 360 degrees it can easily deburr holes, edges leading and trailing, and shapes equally.

- Large Dwell Time: As the rotary brush-barrel rotates, the brushes are counter rotating and the entire carousel spins. This creates a large dwell time for the brushes to work on the material.

- Can Run Dry: There’s no need for coolant. Different materials can be run without changing the brush and parts stay dry, which eliminates the need for expensive drying processes.

- Comes with a Vacuum Conveyor Belt: That will allow for the running of small parts.

- Consumable Costs are Significantly Less than Belt Sanders: It’s easily 1/2 to 1/3 the cost.

Profimach is renowned for offering the world’s broadest and most affordable line of industrial metal finishing machines. Its rotary brush-barrels are built to deliver everything your shop needs: perfect edge rounding, low tooling costs, and variable handling for materials of different types, thicknesses, and sizes.

Profimach’s two most popular rotary brushes are:

- The PRO Steel® PSG Versatile Series is offered in 800 mm, 1000 mm and 1300 mm wide models.

- The PRO Steel® PSRG Versatile PLUS Series is offered in 800mm and 1000 mm wide models equipped with afull width abrasive belt head as well

Profimach’s rotary brush-barrels are engineered to fully and uniformly deburr your part’s rough edges. They can be safely used with flat, shaped, and 3D workpieces and won’t harm coatings like laser film, cladding, or zinc.

Whether your shop uses a laser cutter, a punching machine or plasma cutter, Profimach’s rotary brush-barrels help you produce flawless products and unparalleled results every time.